MakMax Tensile Membrane Structures

With 100 years of experience in the tensile membrane business, MakMax Australia, and the rest of our Taiyo Kogyo Group family have been fortunate to have constructed hundreds of tensile membrane projects all over the world. Two of the most common tensile membranes for use in Architectural Fabric Structures use are PVC (coated polyester fabric) and PTFE (coated glass fibre fabric). We have had the opportunity to field test both PVC and PTFE membranes from a variety of base-fabric manufactures and have complied a brief PTFE vs PVC Membrane Comparison.

It’s worth noting that there are many manufacturers and products available within each material type. MakMax only use materials from premium quality suppliers and all of our chosen membranes have undergone testing in our Japanese research facility to ensure they are fit for purpose.

PTFE Tensile Membrane

PTFE coated fibreglass membranes are currently the best tensile fabric products available in the market. The materials are UV stable, inert and have a proven design life of at least 50 years. They exhibit a high translucency, an extremely low surface energy which minimises dirt build up and maintenance intervals, and the best fire performance characteristics of any tensile membrane material.

PTFE roofing and shade structures feel much brighter and lighter underneath due to the significantly higher light transmission properties. The PTFE coating is inert and does not degrade under UV, so it retains its crisp white colour over time. The low-surface energy of the coating provides excellent natural self-cleaning properties.

A premium roofing option, the main advantage of PTFE over PVC is longevity – the additional investment of installing a PTFE roof will reap benefits over the extended life of the structure.

PVC Tensile Membrane

PVC (coated polyester fabrics) are an excellent weatherproof membrane for tensile membrane structures and the most widely used fabric in architectural applications around the world. They offer a medium level of light transmission, so ideal for smaller sports courts and carpark shade structures. PVC membranes with a PVDF coating have good dirt repellent characteristics however, PVC is more susceptible to UV exposure, so naturally weathers and can degrade over time, requiring a more dedicated maintenance and cleaning schedule. Premium-quality PVC will still reliably last for 20-25 years of service and can be easily replaced at this time, so is still a popular choice for

Used in a wide range of structures, PVC fabric comes in a range of weights designed for different applications. MakMax uses lighter and thinner PVC on our commercial umbrellas and TensoCar shade structures, and a heavy-duty architectural-grade PVC membrane for our TensoSport and TensoSport-MAX canopies.

Key Differences Between PVC vs PTFE Membranes

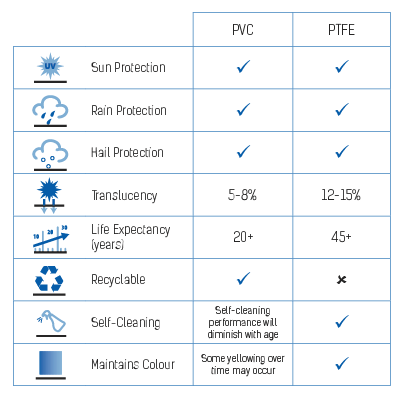

- Both PVC and PTFE effectively block UV rays.

- Both PVC and PTFE membranes are weatherproof†.

- A more affordable option, PVC is also recyclable at the end of the usable life in some regions of the world.

- Available in a range of thicknesses and topcoats, PVC membranes are suited to a huge range of structures, from umbrellas to large-span sporting structures.

- PTFE is almost always white or sandy-coloured. PVC offer more choice in colour (depending on your structure type).

- PTFE membranes have a significantly higher translucency, providing a higher light level under the material which helps reduce artificial lighting during the daytime and provides a much brighter and inviting space than darker canopies.

- Both PVC and PTFE membranes have smooth, low-friction surface coatings that repel dirt and pollutants and under normal rainfall conditions, and have some degree of self-cleaning properties. PTFE offers the lower surface tension, this results in better self-cleaning ability, and lower cleaning and maintenance costs throughout the life of the structure.

- While both PVC and PTFE are durable and hard-wearing materials, PTFE membranes have a significantly longer life-span, maintaining their colour, strength, and performance over much longer periods.

† Comparison based on solid membrane structures; PVC and PTFE are also available in mesh versions.

Fire Performance of PVC & PTFE

PTFE membranes have superior fire performance characteristics to PVC membranes to most Australian and International fire testing standards. For more information on Fire Performance, please refer to the Fire Performance of Different Membranes article.

Do You Have A Project And Need Some Advice?

MakMax Australia offers a range of the best PVC and PTFE membranes in the world from suppliers who have passed our rigorous quality testing and share our commitment to quality, longevity and performance. We recommend membranes with the most suitable properties for attractive and long-lasting tensile membrane structures. Contact us to discuss your project and let us help choose the best tensile membrane.