What is ETFE Foil?

ETFE (Ethylene Tetrafluoroethylene) is durable, highly-transparent, environmentally friendly and a lightweight alternative to glass structures. It’s the new generation material which goes beyond glass.

Polymers were once viewed as a cheap & inferior building material, however, with advanced research and development into architectural, this modern fluoropolymer is now being taken seriously as a legitimate part of the architect’s toolbox.

A durable and lightweight membrane, it is increasingly becoming the material of choice for skylight applications and architectural building facades, and often used in conjunction with, or as an alternative to other tensile membrane materials for roofing structures. The flexible nature of the membrane offers an elegant and modern design alternative.

10 Benefits of Using ETFE Foil In Architecture

1. Light Transmission

- ETFE foil can be highly transparent (up to 90% to 95%), allowing natural sunlight and UV into a building. This offers a range of proven benefits for building inhabitants, from reducing stress and boosting the immune system, to allowing for the natural growth of indoor gardens.

2. Durable

- ETFE is robust and unlikely to degrade after exposure to environmental pollution, UV light, harsh chemicals, or extreme temperature variations.

- Made from a polymer, the membrane will not rust like steel, or weaken over time like glass.

- Highly flexible under stress. ETFE will not shatter like glass in earthquakes or intensive storms.

3. Safety in Design

- ETFE has beneficial characteristics in a fire situation; Low flammability; Low smoke emission; Self-expiring drops (will melt away but does not drip); and Self-extinguishing immediately when fire source is gone.

- With a thickness of 0.05 – 0.3mm, the foil has an extremely low mass so less likely to be a contributing factor in a building collapse.

- Unlike glass, ETFE will not shatter under hail, snow, storm winds, or during a fire.

4. Environmentally Friendly

- From extruding of the film to transportation to site, compared to other similar cladding material, little energy will be consumed, thus reducing the overall carbon footprint.

- In addition, the nature of ETFE systems enhances the building physics through insulation and natural light transmission, contributing to the global low energy aspect of the building.

- The sustainability of the TensoSkyTM ETFE system with Fluron® ETFE-film has been assessed by Germany’s Institut Bauen und Umwelt e.V. The system has been awarded an Environmental Product Declaration: EPD-TAI-20190092-ICB1-EN

5. Recyclable

- Easily recyclable, waste from the manufacturing process or even old elements can be remolded into new products such as tubing components and wires.

6. Cost Effective

- Thanks to the lightweight nature of the membrane material, substructure support systems and concrete foundations can be designed more efficiently.

- ETFE systems also provide ample natural daylighting, thus minimising energy costs by lowering the demand for indoor lighting.

- Easy to repair; small tears to the membrane can be site welded or patched, and commonly installed in separate cushions, individual panels can be replaced if required, rather than having to replace entire roof sections.

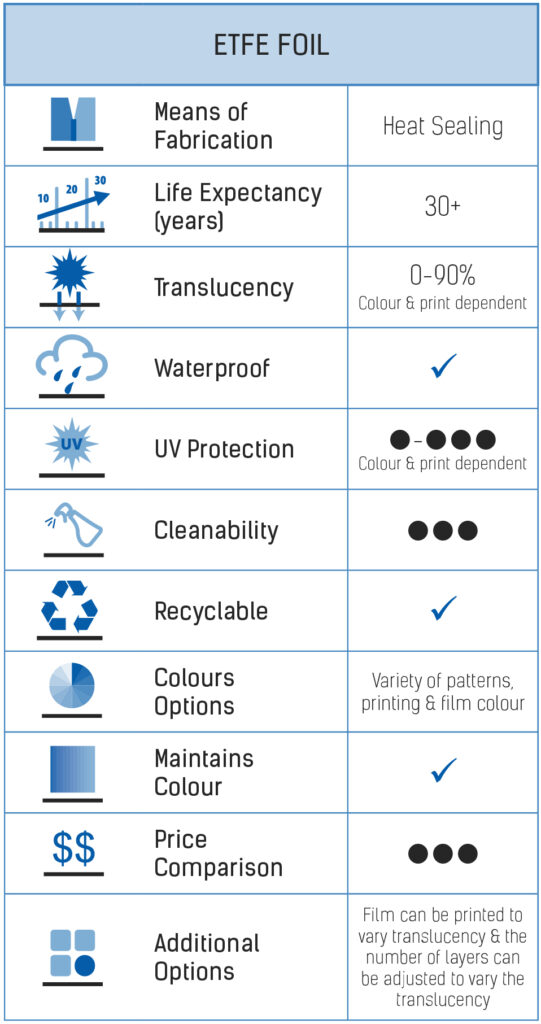

7. Colours

- Colours can be introduced in a variety of ways. It can be applied during the film extrusion process providing a consistent tint in various tones from red to violet or by incorporating lighting with changeable colour options into the structure design.

8. Thermal & Acoustic Insulation

- Using Dual and Triple Layer applications of ETFE creates cushions of air which provides temperature and acoustic insulation.

9. Solar Control

- ETFE foil systems can incorporate a number of different frit patterns on one or more layer to alter solar performance. The foil can be printed with various standard or custom patterns.

10. The WOW Factor

- Architects around the world have begun to embrace the limitless possibilities of this amazing material to create amazing building designs; the 9 benefits above all combine to create some truly iconic urban architecture.

Case Studies | Singapore & Hobart

Fire Performance

Ethylene Tetrafluoroethylene films have been rated under different national and international standards as self-extinguishing with no burning drops.

Melting point is approximately 240 degrees C. When ignited the material quickly melts and shrinks away from the flame/ignition source very similar to thermoplastic behaviour. It does not sustain ignition by itself – once a flame source is withdrawn the material will not continue to combust. Fire test reports supplied confirm it produces no melting droplets and does not provide a spread of flame.

ETFE Cladding Compared to Glass

| Material Layers | Single Layer | Double Layer | Triple Layer | Single Glazed | Double Glazed |

| Material Thickness | 200microns | 200microns x 2 | 200microns x 3 | 6mm | 6mm x 2 |

| Weight (kg/m3) | 0.35 | 0.7 | 1.05 | 15 | 30.3 |

| Visable Light Transmission (%) | 90.5 | 82.4 | 75.4 | 88.9 | 79.6 |

| UV Transmission (%) | 83.5 | 71.5 | 62.3 | 61.4 | 45.5 |

| U-Value (w/m2l) | 5.8 | 2.6 | 1.7 | 5.9 | 2.9 |

Approximate values used a comparison only. TensoSky System values are based on Natural (clear) composition. Glass values are based on clear (untinted).

For specific project requirements, different material weights, surface treatments and print-types are available..

The History of ETFE

Originally developed by DuPont over 40 years ago as an inert coating material for the aerospace industry.

First application in the building industry took place in the early 1980s in Europe

Gained recognition with three major projects, the Eden Zoo Project in 1998, the Allianz Arena for the 2006 Soccer World Cup and the “Water Cube” at the 2008 Beijing Olympics.

Article: ETFE, The Rise of Architectures Favourite Polymer, Patrick Lynch

Would You Like More Information?

Contact us today to discuss your project requirements. We are the market leader in the design, engineering, fabrication and installation of custom fabric structures for a wide variety of applications and industries. We have extensive project experience and offer endless possibilities when it comes to custom design solutions to meet your needs.