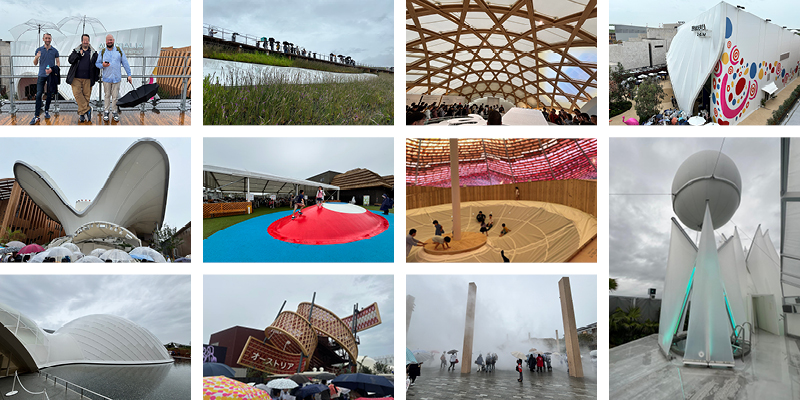

In early June, a small contingent from MakMax Australia had the privilege of travelling to our global head office in Osaka for the Taiyo Group Global Meeting, an incredible gathering of expertise from across the Taiyo/MakMax family of companies. The event brought together colleagues from across our international network; Birdair (USA), Taiyo Europe (Germany), Taiyo Middle East (UAE), Shanghai Taiyo (China), Taiyo Tent (Thailand), MakMax Australia, and of course our head office hosts at Taiyo Kogyo (Japan). With representatives from across all parts of the business; management, engineering, construction, project management, sales, PR and marketing, and even a few members of corporate legal team (just to keep us all in line), it was a great opportunity to connect, share insights, and align our global direction.

Across a full agenda of presentations and discussions, including a welcome address from the President of Taiyo Kogyo, Mr Yuki Nohmura, we explored trends in the tensile membrane industry, shared innovative product and business model ideas, and reinforced the importance of working together across borders. It was clear throughout the meeting that we’re all driven by the same philosophy: “We redefine what membranes can be, transforming any space, experience or environment.” That mindset is what allows the Taiyo Group to keep pushing the envelope, technically, creatively, and collaboratively.

As a cherry on top of a productive and inspiring global meeting, we were also fortunate to have the chance to visit the Osaka Expo 2025 site, where the Taiyo Group’s expertise is on full display.

Tensile Membranes Takes Centre Stage At Expo

Taiyo Kogyo and the wider MakMax Group have a proud history of involvement in world expos, dating all the way back to Osaka 1970. From Brisbane 1988 through to Milan 2015 and Dubai 2020, we’ve pushed the boundaries of what fabric architecture can achieve. And now, at Osaka Expo 2025, we’re doing it again.

Here are my personal top 10 pavilions/structures featuring Taiyo Kogyo/MakMax Group involvement, showcasing brilliant design, complex engineering, and the unique potential of tensile membrane structures.

1. The Grand Ring

The Grand Ring is the centrepiece of the Osaka Expo 2025 and quite literally unites the world by encircling the global expo. Stretching around two kilometres in circumference, this enormous circular structure encircles the main Expo site, with only a handful of pavilions located beyond its outer edge. Designed by architect Sou Fujimoto, the Grand Ring embodies the concept of “Unity in Diversity” through its continuous, flowing form.

Taiyo Kogyo was responsible for fabricating and installing the PTFE membrane roof sections across two-thirds of the Grand Ring. The translucent membrane helps to light the interior of the massive wooden colonnade with soft, natural light during the day, creating an inviting space that is both functional and architectural. The scale alone is impressive – it covers an area of 61,035 square metres (656,980 sq ft), making it the largest wooden architectural structure on earth (certified by Guinness World Records).

We had the chance to experience the Grand Ring from both above and below. The elevated walkway running along the top offers one of the best vantage points on site, a great way to get a bird’s-eye view of the incredible pavilions spread out across the expo grounds. The wide covered walkway beneath the ring provided shelter from the weather, letting us explore the outer areas of the site without the awkward dance of umbrellas and soggy brochures. As both a viewing platform and a sheltered thoroughfare, the Grand Ring delivered form, function and visual impact in equal measure.

2. Iida Group × Osaka Public University Pavilion

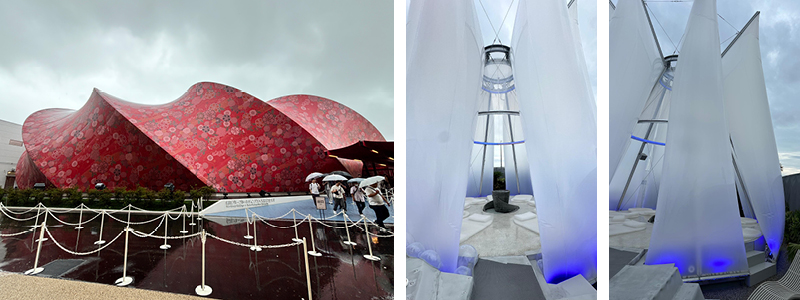

This pavilion is a beautiful example of blending traditional craftsmanship with modern membrane technology. It’s the world’s first building clad entirely in Nishijin brocade, a richly patterned silk fabric traditionally used in Kyoto’s kimono industry. To adapt this material into an architectural membrane, Taiyo Kogyo developed a specially treated version that could withstand the elements while preserving the delicate appearance and intricate pattern.

Working with a complex steel frame, the Taiyo team used detailed 3D modelling and precision manufacturing to match the brocade pattern seamlessly across the surface. Factory jigs ensured exact alignment and tensioning, which was no small feat given the curved forms and tight tolerances. The result is a pavilion that quite literally wraps sustainability and tradition into a single, flowing form – an architectural expression of the theme “Sustainable Mobius.”

3. Expo Sauna Taiyo no Tsubomi

Not your typical membrane application, this structure is a working sauna facility clad in ETFE film. Taiyo Kogyo designed and installed the ETFE cushions to follow the curved, petal-like shape of the sauna pod, creating a soft, glowing structure that diffuses natural light and maintains a bright, inviting interior.

The air-filled ETFE cushions offer some natural thermal insulation while remaining lightweight and visually striking. The flexibility of the film allowed Taiyo to shape the form organically, while the air-filled cushions help trap warm air (perfect for a functioning sauna). Construction was handled by the local team TSP Taiyo, and ACTIO (Taiyo Group’s event and venue management division) manages the day-to-day operations. It’s a wonderful showcase of membrane versatility and multidisciplinary coordination.

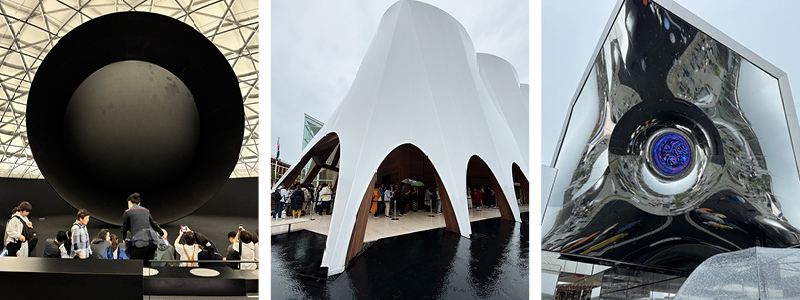

4. Blue Ocean Dome

The Blue Ocean Dome houses immersive marine education exhibits, including a 10-metre spherical screen showing a powerful 3D multimedia film documenting underwater environments and highlighting the impact of ocean pollution. With an overarching theme of sustainability and resource management, the Blue Ocean Dome (actually three separate domes within one pavilion) embodied the challenge of innovating construction through sustainable materials. Each dome featured a different structural approach: laminated bamboo beams in the first, a diagrid shell formed with carbon-fibre supports in the central dome, and compressed cardboard members with wooden nodes in the final dome.

Taiyo Kogyo was responsible for designing, manufacturing, and installing the custom membrane outer shell for each dome. The chosen material had to be flame-retardant, highly transparent, and structurally sound over a large span, all while being installed in a limited footprint. The translucency of the roof allows natural light to enhance the exhibits during the day, while at night it transforms into a softly glowing beacon. The precision required to tension such a large single-piece membranes without visible creases or distortions speaks to Taiyo’s technical expertise.

5. Qatar Pavilion

Designed by Kengo Kuma & Associates, the Qatar Pavilion is inspired by traditional Qatari dhows and Japanese wooden joinery, two cultures with strong maritime heritage. The standout feature for me was the flowing, sculptural membrane façade that captures the movement and grace of wind-filled sails.

Taiyo Kogyo worked on the membrane design, fabrication, and installation. The technical challenge here was the integration of the membrane with the timber and steel substructure, maintaining the visual fluidity while ensuring structural performance. The membrane acts as both shading element and visual metaphor, combining aesthetic impact with functionality. It’s a great example of architectural storytelling using tensile materials.

6. null2 Pavilion

At first glance, the null2 Pavilion looks more like a piece of digital art than a traditional building. Its façade is made of a highly reflective mirror membrane stretched across a boxy aluminium frame. As visitors move around it, the building reflects and distorts the surroundings, creating an ever-changing visual effect. Hidden elements behind the membrane stretch and move the membrane, creating a kinetic visual feast.

This custom-developed mirror membrane was a technical leap. Taiyo Kogyo handled the membrane design, fabrication, and mounting system, including the reflective film and all supporting hardware. Achieving a flat, tensioned surface without ripples or distortion in a mirrored membrane requires precision engineering and careful installation. The result is a striking kinetic-like experience, a building that disappears into its environment, depending on your angle.

7. Playground of Life: Jellyfish Pavilion

With a name like Jellyfish Pavilion, you know it’s going to be something a little different. The structure features a voluminous, free-form membrane roof supported by an irregular web of steel trusses. This organic, floating canopy was designed to represent life’s unpredictability and diversity – an inclusive space encouraging free and imaginative play.

Taiyo Kogyo developed and installed what’s known as a Taiyo Truss Roof (TTR), combining custom steel TM trusses with tensile membrane panels. The challenge was creating a roof that appeared soft and fluid, yet met all the structural and performance requirements for public safety. The form, though whimsical, required advanced structural modelling and bespoke membrane cutting patterns to achieve the fluctuating aesthetic.

8. Osaka Healthcare Pavilion: Nest for Reborn

This pavilion explores the future of urban healthcare and regenerative medicine, with a stunning architectural feature: multiple ETFE membrane roofs shaped like overlapping, translucent leaves. Water flows across the surfaces, either cascading gently like a waterfall or travelling in smooth, even streams, depending on the weather.

Taiyo Kogyo designed, manufactured, and installed the truss-and-ETFE roof system, simulating water flow through advanced surface modelling and drainage design. Not only did the membranes need to perform structurally and visually, but they also had to interact with the natural element of water ,an added layer of complexity that elevates this pavilion from striking to spectacular.

9. Future of Life Pavilion

This pavilion’s theme, Amplification of Lives, is visually expressed through the movement of water along a black mesh membrane façade. Installed in relief over a rigid structure, the mesh membrane has been carefully shaped to channel water flow, creating a wave-like effect that animates the surface and reflects light in motion.

Taiyo Kogyo’s role was to design, manufacture, and install this specialised mesh membrane system. The material selection had to balance transparency, durability, and hydrodynamics. Engineering the flow paths for consistent water movement required meticulous coordination between architectural design and fluid dynamics, an elegant merging of art and environmental design.

10. PASONA Natureverse

Based on the theme Thank You, Life, the PASONA pavilion is both futuristic and organic. Its pink spiral membrane roof mimics the curled form of an ammonite shell, symbolising the connection between natural evolution and biotech advancement, particularly, the use of iPS cells to regenerate heart tissue.

Taiyo Kogyo engineered the membrane roof and base steel structure, creating a sculptural form that evokes motion and life. The choice of colour, form, and material came together to create a pavilion that feels alive, lightweight, immersive, and full of meaning. The precision-cut panels required advanced modelling to achieve the fluid, shell-like shape while maintaining structural integrity.

Honourable Mention: Yumeshima Station Roof

While not one of the pavilions, the Yumeshima Station Roof deserves a special mention, if only because it was the last structure I saw on the way out of Expo, after 24,000 steps and a full day exploring a world of imaginative designs.

The station, an extension of the existing Cosmosquare Line, acts as the main public gateway to Expo 2025. The barrel-vault canopy covering the station’s escalator entrances was designed and installed by Taiyo Kogyo, providing a sleek, durable and weather-resistant welcome (or farewell) to visitors. The PTFE membrane selected for the canopy was chosen for its strength, light weight, and long-term performance. The structure is a quiet yet refined piece of tensile architecture, offering both practical shelter and a subtle architectural gesture that bookends the Expo experience.

A fitting farewell to Expo 25, it encapsulates so much of what makes the Taiyo Group’s work exceptional: thoughtful, efficient, sustainable design, executed with quiet precision.

My Final Thoughts on Osaka Expo 25

Despite the soggy conditions, seeing all of these structures up close was incredibly inspiring. As a representative of MakMax Australia, I was proud to see how our global network continues to shape major international events through cutting-edge membrane design. The creativity, scale and technical complexity of the Osaka Expo 2025 pavilions reminded me why I love this industry – it’s where art and engineering meet, with fabric as the medium.

If you’re heading to the Osaka Expo this year (it’s on until October 13th 2025), make sure you check out the incredible tensile membrane architecture on display, there’s a good chance the roof above your head came from the Taiyo/MakMax Group.