STFE – Transparent Strength for Tensile Architecture

WHAT IS STFE?

STFE is a next-generation composite membrane developed specifically for tensile architecture. Designed as a lightweight, transparent alternative to traditional glazing systems, STFE provides both structural integrity and visual openness, making it ideal for façades, skylights, and large-span roofing applications.

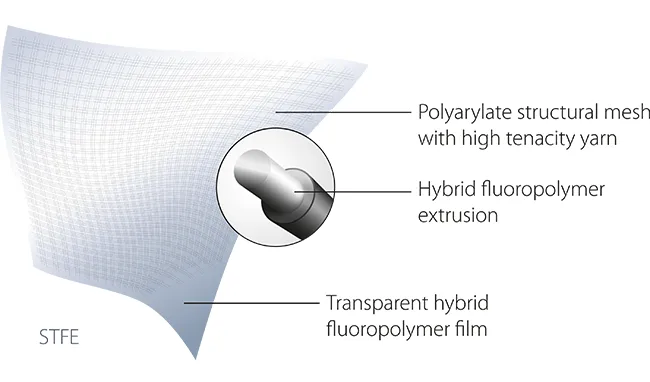

The membrane is composed of a high- strength polyarylate fibre mesh (an advanced engineering plastic known for its durability and chemical resistance) encapsulated between layers of transparent hybrid fluoropolymer film. This composite construction forms a highly effective partnership: the internal mesh delivers mechanical strength and spanning capability, while the outer fluoropolymer layers ensure weather resistance, UV protection, and visual clarity.

CASE STUDY

MPavilion 2022 STFE Layer

A unique structure made up of many elements and many contributors working together to realise the ultimate vision, MakMax create the middle STFE layer to the structure.

Key Benefits of STFE

TRANSPARENCY WITH A VIEW

STFE offers a unique combination of structure and visual transparency. Up close, the fine woven mesh is clearly visible, but from a distance, it becomes nearly imperceptible. This effect, referred to by the manufacturers as the “Sun Glass Effectt” which is comparable to a depth blur in photography, where a foreground object (like a fence) fades from view when a camera is focused on a background subject.

Similarly, STFE allows the structure to seemingly vanish into the sky or surrounding environment, maintaining the feeling of openness while still delivering protection from the elements.

STRUCTURAL STRENGTH

The inner polyarylate mesh offers a mechanical resistance of up to 8 tonnes per linear metre, enabling long free- span designs with reduced secondary support structures. This not only streamlines installation but also contributes to a lighter structural footprint, both physically and environmentally.

Compared to conventional glass and steel systems, STFE is over ten times lighter. This weight reduction can translate into savings in structural steel, foundation requirements, and transportation, all of which support more sustainable construction practices.

NATURAL LIGHT TRANSMISSION

With approximately 50% light transmission, STFE brings abundant natural daylight into interior spaces. It also permits a moderate level of UV light, making it suitable for environments where plant growth or a connection to the natural world is essential. Whether used in a biosphere, a botanical garden, or a public atrium, STFE creates bright, welcoming spaces that feel open and connected to the outdoors.

LOW MAINTENANCE

STFE’s fluoropolymer outer layers provide excellent resistance to weathering, UV exposure, dust, fungal growth, and atmospheric pollutants. These properties mean STFE structures require very little maintenance, retaining both appearance and performance over time.

FLEXIBLE ARCHITECTURAL DESIGN

Thanks to its composite and flexible nature, STFE opens new possibilities in architectural form and expression. The membrane can be tensioned across a range of geometries, including curved, flat or sculptural surfaces.

Panels are welded together using a black STFE Cover Tape, which, while visible, can be designed into the overall aesthetic, forming intentional lines, patterns or grid motifs across the membrane surface.

IDEAL APPLICATIONS

STFE is best suited to architectural environments that demand both weather protection and visual openness. Its unique combination of lightness, strength and transparency makes it an excellent choice for:

- Stadiums and sporting venues – offering covered stands with natural light and open-air ambience.

- Botanical gardens, zoos and biospheres – enabling UV transmission for plant growth while providing shelter.

- Shopping centre atriums – protecting large open areas while preserving a connection to the outdoors.

- Hotel courtyards and lobby spaces – blending elegance with light- filled architecture.

- Airport terminals and transit hubs – delivering expansive, column- free zones with clear sightlines and daylight.

- Amphitheatres and large public structures – creating weather- protected performance or gathering spaces that maintain openness and visual appeal.

Whether your design calls for drama, delicacy or daylight, STFE offers a bold alternative to glass; lightweight, strong and visually striking.

Tenseo Xtrem STFE 50 membrane is a product designed by the Serge Ferrari Group. For more details, visit the STFE page on the Serge Ferrari website. As a new product, MakMax was the first fabricator in Australia to use STFE (as part of the MPavilion 2022 Structure).

We are currently working on an exciting STFE project in Victoria; details and project photos be published here once complete.

Would You Like More Information About STFE Structures?

Contact us today to discuss your project requirements. We are the market leader in the design, engineering, fabrication and installation of custom fabric structures for a wide variety of applications and industries. We have extensive project experience and offer endless possibilities when it comes to custom design solutions to meet your needs.