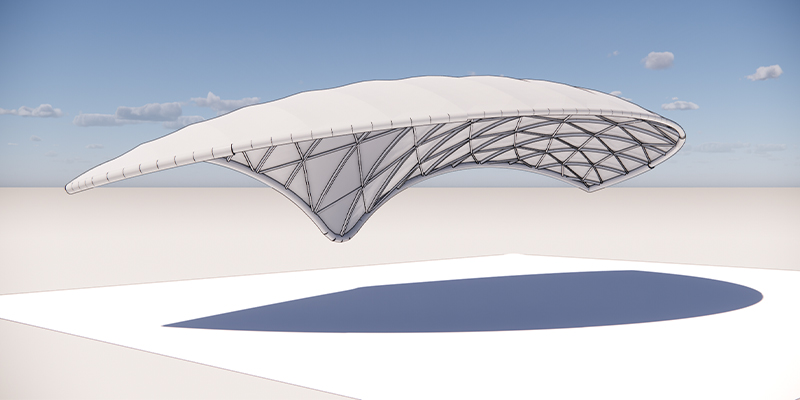

Tumbalong Green Amphitheatre Roof

Project Details

Location: Darling Harbour, NSW

Completion Date: March 2024

Size: 1000 sqm

Fabric: PVC - Serge-Ferrari TX30-II

Client: Kane Constructions / Darling Harbour Live

The Tumbalong Green Amphitheatre Roof is a remarkable marriage of beautiful elements and engineering expertise. The enormous sound shell (looking remarkably similar to a natural shell you might find at one of Sydney’s many beaches) curves up and over the performers, allowing sound to wash out over the audience like a breaking wave.

An example where architectural design meets functionality, one of the key elements of the structure is the combination of Cross Laminated Timber (CLT) and Tensile Membrane to create a lightweight, and visually appealing stage roof.

The Brief

Kane Projects, the head contractors on the Tumbalong Green job worked with the TTW, who were the structural engineers for the project, and responsible for the design and detailing of all the timber, steel and concrete elements. Together with the Cross Laminated Timber (CLT) supplier, Theca Australia, and MakMax, the project team worked to bring the stunning Hassell designed amphitheater to life.

MakMax Australia’s scope on the project was to design and engineer the architectural fabric cladding that makes up the outer layer of the stunning Tumbalong Green Amphitheatre Roof. This included the three dimensional form-finding and patterning of the fabric to achieve the desired multi-plane curvature, as well designing our TensoShade extruded aluminium fixing system to interface with the steel and CLT elements of the roof.

The Concept

The wide cantilevered shell is only anchored at three small points, creating a light and open structure. The beautiful CLT timber diagrid shell is clad in a high-tech, modern architectural PVC fabric, with the entire structure frames in a roll-steal black-painted frame.

The Materials

While multi-directionally curved tensile membrane structures offer stunning aesthetics and design freedom, they also pose significant engineering and construction challenges. MakMax successfully tackled these obstacles through our expertise in tensile membrane engineering and the use of specialised parametric modeling software.

Designing multi-directionally curved membranes demands sophisticated form-finding software to ascertain the optimal cutting pattern and pre-stress loads necessary for achieving the desired final form while ensuring proper tension distribution.

Fabric selection is another critical aspect in constructing multi-curved structures. Fabrics with higher elasticity and flexibility are often essential to accommodate the complex shapes without generating excessive stress concentrations.

For the Tumbalong Green Amphitheatre Roof, we selected Serge Ferrari Flexlight Xtrem TX30-II, an architectural PVC renowned for its high performance in tensile architecture applications such as roofs. With its crosslink technology, TX30-II boasts exceptional durability, ensuring a prolonged lifespan, making it ideal for permanent outdoor structures like amphitheater roofs. Thanks to Serge Ferrari’s Precontraint technology, TX30-II maintains its shape effectively, enduring wind and minor temperature fluctuations with ease. This dimensional stability is paramount for a large multi-curved roof structure.

The Result

Creating a showpiece architectural structure in Darling Harbour, the Tumbalong Green Amphitheatre is a remarkable marriage of beautiful elements and engineering expertise. The soundshell curves up and over the stage, allowing sound to wash over the audience like a breaking wave.

An example of architectural design meets functionality, the combination of Cross Laminated Timber (CLT) structural elements supporting an 1000 square metre PCV membrane have created a lightweight, and visually appealing stage roof.

The Tumbalong Green Amphitheatre Roof has won a number of tensile membrane industry awards;

- Winner STA Australian Textile Fabrication Industry Awards 2024

Tension Structures – 250sqm to 2000sqm - Award of Excellence LSAA Design Awards 2024

Medium Structures - Award of Excellence – ATA International Achievement Awards 2024

Frame-Supported Structures