Link @ Langley ETFE Atrium

Project Details

Location: Perth, WA

Completion Date: February 2024

Size: 1665 sqm

Fabric: ETFE - AGC Fluon 300um (P46D16)

Client: Byte Construct / Grand Hotel Group

Photography: © Sky Skills Industries

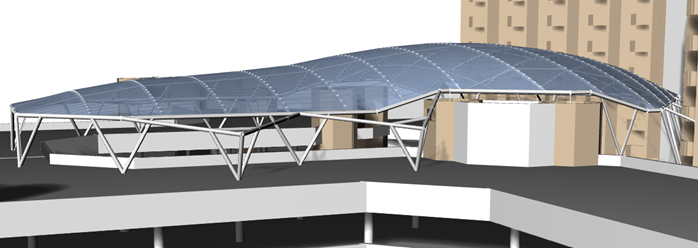

Nestled along the picturesque Perth riverside, the Link @ Langley ETFE Atrium stands as a testament to innovation and design excellence. This custom-designed, 1665 sqm single-layer ETFE canopy crowns the central atrium of a revitalised shopping, dining, and entertainment district, transforming the former Fortescue Metals HQ into a contemporary urban hub.

The Brief

The architectural vision for the Link @ Langley ETFE Atrium was clear – create a visually striking, yet functional skylight element to enhance the appeal of the riverside redevelopment. The challenge was to seamlessly integrate the canopy structure with the existing buildings, providing a light, transparent and waterproof atrium for the new entertainment precinct.

The Concept

The undulating canopy of the Link @ Langley ETFE Atrium mimics the fluidity of a breaking wave, adding a unique and dynamic touch to the redevelopment project. MakMax worked closely with project architect, Hodge Collard Preston Architects, to design the atrium structure.

ETFE (Ethylene Tetrafluoroethylene) is durable, highly transparent, and extremely lightweight in comparison to glass structures (upto 20x lighter than a glazed roof). This modern membrane is considered the material of choice for large atrium applications. The lightweight and flexible nature of the membrane offers an elegant and modern design alternative.

The Materials

Forming part of Stage 2 of the new development, MakMax and our specialist ETFE installation partner, Sky Skills Industries, worked closely with head contractor Byte Construct to install the Link @ Langley ETFE Atrium. Even with the ultra-lightweight ETFE cladding, the massive area covered by the TensoSky atrium uses 74t of structural steel. A unique structure, the steel framework for the Link @ Langley ETFE atrium has been designed to retrofit onto the existing buildings, making use of the rooftop of the former Fortescue Metals HQ, as well as using anchor points on the vertical rear face of the adjoining Hyatt Regency Hotel.

The supporting steel on the atrium canopy is coated with a PUR5 (3-coat polyurethane) architectural paint system, designed to maintain colour and protect the steel from corrosion.

The single layer ETFE features a 16mm silver-dot frit pattern (P46D16 ) on the underside of ETFE. This provides solar gain protection, while still offering a translucency of 64%. The fit pattern is used to suit the atrium’s thermal and optical requirements.

The ETFE panels are supported by almost 200 GR316 stainless steel cables, threaded through specially designed and fabricated cable pockets welded to the underside of the ETFE. The cables are attached the steel rafters and then tensioned to create a solid exoskeleton to support the equally membrane. The ETFE is attached the steel frame via MakMax’s proprietary TensoSky single entry anodised aluminum ETFE clamps.

The canopy incorporates a bird-friendly repellent system consisting of sprung light gauge stainless steel parallel wires on stainless steel upstands to prevent perching (potentially causing damage to the ETFE).

The Result

The Link @ Langley ETFE Atrium not only enhances the visual appeal of the riverside redevelopment but also demonstrates the successful fusion of modern design with practical engineering solutions.

The result is a harmonious blend of form and function and a symbol of innovation, seamlessly integrating into its surroundings while offering a captivating architectural aesthetic . This project exemplifies the power of thoughtful design and cutting-edge materials in shaping the future of urban architecture.

The Link@Langley ETFE Atrium has won the following Tensile Membrane Industry Awards

- Winner STA Australian Textile Fabrication Industry Awards 2024

Internationally Fabricated Projects - Citation of Merit – LSAA Design Awards 2024

Large Structures - Outstanding Achievement – ATA International Achievement Awards 2024

Freestanding Structures